Picking the right wheel can seem like a daunting task when looking at the number of wheels on the market. For there to be so many wheels, they much each have a unique ride, right? How can anyone possibly pick a wheel without second guessing every decision?

Our goal is that after reading through this guide you will not feel so lost in the world of wheels and be able to choose exactly what you want. There are several factors that go into choosing a wheel. They are listed below, but we will go into more details through the article.

After this, we will talk about pavement and urethane types. These factors also play a major role in the feel of a skateboard wheel.

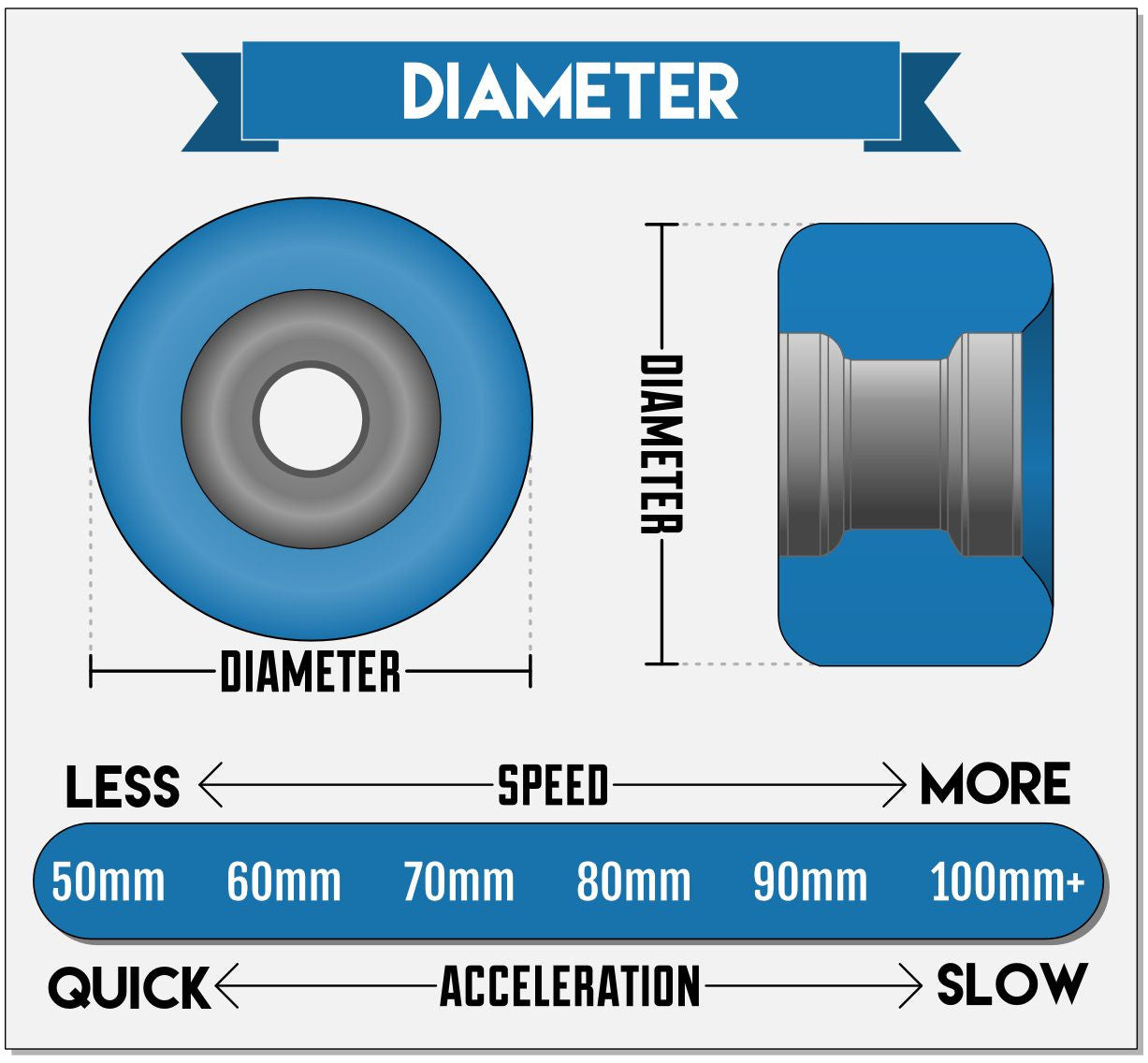

- Diameter

- The diameter of the wheel measured in millimeters. The bigger the wheel the smoother the ride, but the more weight to push around. Also going too big might get dreaded wheel bite. Generally for longboarding a 70mm - 80mm wheel is ideal.

- Width

- The measurement from the furthest point out on the wheel face to the furthest point on the wheel back. Using this measurement can help determine if a wheel is too big for a set up, however, it is not very commonly referred to.

- Durometer

- The hardness of the wheel measured on the Shore scale. This is the second most common feature of a wheel after size and greatly affects the way a longboard wheel rides. Harder is generally more for sliding and softer is generally more for grip. A wheel around 80a is usually a safe midpoint.

- Contact Patch Size

- The width of the area on the wheel that touches the ground. It is measured in millimeters and can help determine how much grip a wheel gives the rider. The bigger the contact patch, generally the more grippy the wheel will be.

- Contact Patch Surface

- The type of wheel surface that touches the ground. This can be smooth (for grip) or sand stone ground (for sliding). Some companies have their own proprietary wheel surface (such as SlidePreppedTM from Fireball).

- Edge Type

- The shape of the outer most lip on the longboard wheel. This can be rounded (for sliding), square (for grip), or beveled (combination of slip and grip).

- Core Position

- The location of the core within the longboard wheel. The three types of positioning are sideset, offset, and centerset. Sideset and offset are generally best for grip and centerset is generally best for sliding.

Height/Diameter (mm)

The height of a wheel is the distance between where the wheel touches the ground and the top of the urethane. The larger the wheel, the easier it will roll over cracks and rough pavement. However, the smaller the wheel, the faster it will accelerate going downhill. Often a rider's personal preference will determine the balance between the two.

Wheel measurements are generally given in millimeters (mm) and the height is usually listed in the title of the wheel. For example: Orangatang Kegel 80mm/80a. Going over 80mm can risk of bending the standard 8mm axles of a skateboard truck with aggressive riding.

Width and Contact Patch

The width of a wheel is technically the distance from the outer to inner edge of the urethane, however, most often width is very closely related to the contact patch of the wheel. In fact, width and contact patch can be the same in some wheel shapes.

The contact patch of the wheel is the width of the wheel physically in contact with the ground, excluding the any extra urethane that may be rounded or beveled to make the edge of the wheel. Generally, the wider the contact patch, the more grip a wheel will have. Durometer is also a factor in grip, but we'll get to that next.

Contact patches also come with one of two types of surfaces: Mold Release or Sandstone Ground.

Mold release is not really the correct term, but it just refers to the smooth, glossy surface on a contact patch that has been untouched out of the wheel mold. This surface is very grippy and will require some kind of break in period before sliding well.

Sandstond grind refers to the process of removing the glossy contact patch. This makes the patch feel like a soft baby bottom and allows for easy sliding right out of the box. Almost all good freeride wheels will come with a sandstone grind to lessen the break in period for the wheels.

Durometer (a)

Durometer refers to the measurement of the hardness of the rubbery polyurethane and is represented by a number and a letter, which will typically be an "a" for polyurethane. The lower the durometer the softer and more rubbery the wheel is. Most wheels range from 75a to 100a, where 100a would be a very hard shortboard wheel.

The durometer often comes into play when understanding how the wheel will slide. A higher durometer/less flexible rubber will slide better, where a lower durometer/more flexible rubber will grip. "Grippy" wheels are generally found between 75a-78a; Freeride wheels are generally found in the 80a-87a; and park/slide wheels are found in the 90a+.

It should also be noted that durometer plays a role in the speed of the wheel. Lower durometer wheels grip the road better by deforming. However, this deformation also slows the wheel down. A harder wheel will have less friction on uneven surfaces because it does not deform, but will be faster on smoother surfaces. Everything here is a balance. It is up to the rider to find that speedy sweet spot.

Edge Type or Lips

The lips of a wheel refer to the very edges of the wheel and vary in shape and thickness. Lips and edges control how the wheel grabs the road.

- Round Lips

- Have a rounded appearance and allow the wheel to break traction for slides easier. See Orangatang Stimulus, Fireball Tinder, or Sector 9 Butterballs

- Square Lips

- Have a sheer drop of at the end of the wheel, giving it a squared appearance. This allows for a maximal contact patch, and more grip. See Orangatang In Heat or Orangatang 4President

- Beveled Lips

- Have an angle at the end of the wheel, giving it a sharp, triangle appearance. This allows for a mix of slide and grip. See Fireball Beast or Fireball Incendo

- Thick vs. Thin Lips

- The thickness of a wheels lip refers to the depth of urethane near the outer edges and is generally applied to wheels with square lips. The thicker the lip of a wheel is, the more elasticity it has when deformed in a turn, allowing for a higher rebound and easier return to center, especially at high speeds. A thicker lip will also resist deformation while turning and slide out easier.

The Core

The core is a circular hard plastic (or sometimes hard urethane or aluminum) ring that seats the bearings and gives the rubbery polyurethane a place to attach. For the average rider, the size and shape of the core will make little difference, but it should be noted that a larger core will allow for less deformation of the surrounding urethane, often enhancing the slide-ability of the wheel.

What is really important about the core is its placement within the wheel and its effects on traction. When, going into a slide, the wheels will have the most force put in the inner lip of the wheel. Depending on where the core is placed inside the wheel will determine how much urethane is available to aid the wheels grip. The three core placements are: center set, offset, and side set.

- Centerset

- Centerset cores are often found in wheels made exclusively for sliding. This is because they can be flipped them around (given the urethane shape is symmetrical) and prolong their life. Centerset wheels have the most effective grip. To overcome this for a sliding wheel, the durometer is often high and the contact patch is small.

- Offset

- As logically implied, the offset core is placed off center, closer to the inner side of the wheel. Most wheels in the longboarding world have offset cores because they offer a nice balance of grip and slip to fit almost any ride. If certain characteristics of a wheel are desired, the shape, thickness, and durometer of the urethane is modified to fit the designers purpose.

- Sideset

- Sideset wheels have a core that is placed very close to the inner lip of the wheel. Sideset wheels are notorious for effortless slides due to the minimal urethane on the inner-lip that would be used for traction. Anyone who has heard of the legendary slide of the "Blue Kryptos" knows the effects of a side set wheel.

- Small Cores

- The most urethane around the wheel and generally the most grip. Slower roll speeds.

- Large Cores

- Higher roll speeds and generally less grip. Less deformation during slides leads to more predictability.

Wheel Types

Even though there are a multitude of ways to design a wheel, certain patterns are prevalent for different riding styles. To save time and space, I will define the four general types of wheels for the major riding styles present today: Park/Street, Cruising, Downhill, and Freeride.

- Park/Street Wheels

- These wheels are harder and smaller. This is so that riders can accelerate quickly and perform tricks more easily on smooth skate park surfaces. The hardness of the wheel gives riders some slight give on landings and less hang up on rails/ledges/etc.

Example Park/Street Wheel Specs: Height: ~50mm-60mm; Contact Patch ~15mm-20mm; 90a-100a; Round Lips, generally elliptical; Centerset Core.

- Cruising Wheels

- What a person wants in a cruising wheel could vary highly from person to person, but most will agree that a larger height/width wheel and softer durometer is desired to tackle any pavement and have a fair amount of grip.

Example Cruising Wheel Specs: Height: ~70mm-80mm; Contact Patch ~45mm-55mm; 75a-80a; Square or Round Lips, generally thick; Offset or Sideset Core.

- Downhill Wheels

- Downhill wheels change slightly depending on the application. Riders that want sheer speed will go with something larger and harder. If more technical downhill is demanded, slightly smaller and softer wheels are choice.

Example DH Wheel Specs: 70-80mm; Contact Patch ~55mm; 78a-83a; Square/Sharp lips; Offset Core.

- Freeride Wheel

- Most freeride wheels resemble a traditional "shortboard" wheel in shape, but are larger and have softer durometer urethane. Most will look as if they are centerset, but they are usually slightly offset to add a nice balance between grip and slide. Freeride wheels generally have the largest spectrum of variability in shape, core position, and durometer because the way people slide is very dependent on an individual's size, weight, and riding style. However, going over 75mm for a freeride wheel will run the risk of sliding poorly. This is because the urethane added to give the height will deform and grip, making slides harder to initiate and less predictable.

Example Freeride Wheel Specs: 65mm-70mm; Contact Patch ~45mm; 78a-86a; Round Lips; Offset, Sideset, Centerset Cores.

Pavement Types

Beyond the wheel itself, what type of pavement will play a large role in wheel choice, especially when it comes to freeriding. New riders will often think that new, smooth asphalt would be best for sliding, but it could not be farther from the truth.

Smooth roads (especially asphalt laid in the late 2000's and up) grip a lot more than old or crumbled pavement by effectively allowing for more contact and friction between the wheel and the ground. New pavement will make a wheel feel like it is super grabby and gummy. Old and crumbled pavement will allow for easier slides. The greatest hills have a balance of pavement wear and smoothness.

Photo: Fernando Vega // Rider: Miguel Azanza

It is hard to have a guide for every type of pavement, so keep this information in mind when picking a wheel. The only way to truly know what a wheel will feel like on a new road is to ride it. Always take that first run cautiously.

Breaking In Your Wheels

Taking wheels out for a rough DH/sliding session as a first ride is not a great idea. New wheels that are not sandstone ground will have a shiny rubber surface (mold release) that should be worn down to a smooth, but not slick texture before a heavy session of slides. To wear the wheels just have a carve/cruise session for thirty minutes to an hour with minimal sliding.

Not breaking in wheels before riding will run the risk of causing chunking or damaging the wheel's outer lips. A common trend in freeride wheels is to have their surface stone ground so they are ready to slide right out of the box, eliminating the need to break in the wheels as much, if at all.

Terminology

Large part of finding the right wheel will also depend on researching what other people think about the wheel. A great source for this information is forums, such as the ever popular Reddit or Silverfish Longboarding. Here it is common to find informal terminology that can be confusing at first. Schooling time below.

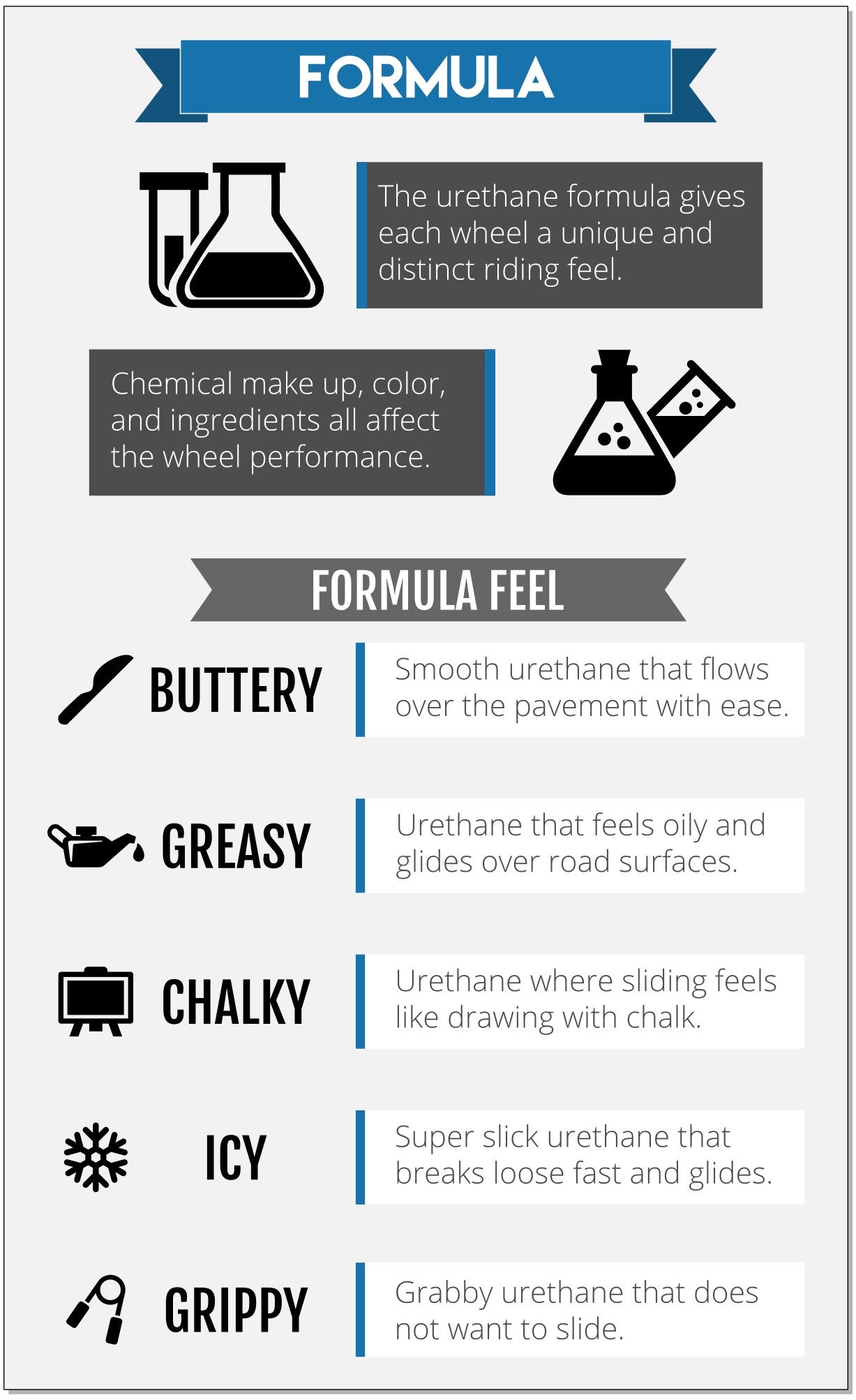

- Thane

- Refers to the polyurethane or urethane formula of a particular company. Since the main characteristics of a wheels ride will be derived form its urethane compound, many people will highly value a company due to its secret formula. Some companies, like Orangatang, have multiple urethane formulas for different lines of wheels.

- Chunking

- Refers to chunks of urethane that get broken off the lips (usually outer) of a wheel. Sometimes it will happen naturally, but most of the time it is due to sliding the wheel before breaking it in.

- Flat Spot

- When pulling long slides, riders should not stand at 90 degrees for too long or it increases the risk of a flat spot on the wheel. This flat spot will negatively affect speed and slide performance.

- Coning

- During a slide, the main force on the wheels is placed on the where the core is located. Usually the core is located on the offset or sideset from the center of the wheel. Physics dictates sliding the urethane will wear out a lot faster at the inner part of the wheel. This gives the wheel a coned appearance with the inner diameter being smaller then the outer. Too much coning can make performance suffer and render a wheel worthless.

- Buttery Slide

- The adjective "buttery" is one of the most positive things heard about slide wheels. This word is used to describe a wheel that slides very smoothly and in control. It literally comes from the feel of spreading soft butter over bread.

- Icy Slide

- When people describe a wheels as having an "icy" slide, it generally means that the wheels break traction very easy and do not regain traction very predictably. Sometimes this is highly desired if a very prolonged, high speed slide is wanted.

- Chatter

- When saying wheels or a slide chatter, it is referring to the sound of a choppy slide. This is often due to the wheels not being broken in enough or a certain urethane/shape combo. Chattery slides are definitely not optimal control-wise and inexperienced riders could be thrown off.

- Grip-up

- This term refers to wheels regaining traction after a slide and continuing to spin normally. Having a wheel that predictably "grips-up" is important when trying to control your speed.

Ultimately, picking the right set of wheels is a matter of doing research and then trying stuff out to discover what works best for your personal ride style.

Anything we missed? Let us know on our contact page!